Structure characteristics of CNC high speed wire cut EDM(1)

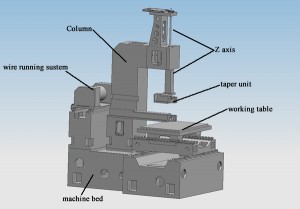

CNC high speed feed wire cut EDM is consisted by main machine and CNC controller. Figure 1-1 is the photo of Suzhou Kingred’s KD series CNC high speed feed wire cut EDM machine. Hereby, we take Kingred’s wire cut EDM as a sample to introduce structure of CNC high speed feed wire cut EDM machine.

- Main machine

CNC high speed feed wire cut EDM machine is composed of machine bed, column, working table, wire running system, taper unit, working solution recycle system, Z axis, water-proof cover. As show in figure 1-2

① Machine bed and column

Machine bed and column are two basic structure of CNC high speed wire cut EDM machine, see figure 1-3, it adopt large “T” shape machine bed, “C” structure column, HT250 casting with resin sand casting technology, compact structure, strong rigidity of whole machine. Column is fixed on machine bed as constructional element, machine bed hold whole machine as a base. Machine bed and column had been age treated to remove inner stress, to reduce deformation. Machine bed is strong enough take whole machine, good ability of anti-vibration, less thermal deformation. Manufacturing and assembly of machine bed and column must meet strict requirement of geometric and mechanical accuracy.

② Working table

Working table supports and holds workpiece. Its movement is controlled by two stepper motors(servo motors of closed-loop control wire cut EDM). The while wire cut EDM machining is finished by relative movement between working table and electrode wire. The working table of high speed feed wire cut EDM machine includes X and Y axis slides, adopts precious linear guideway and precious ball screw as moving components. XY cross structure had been used for decades, the mechanical rigidity and controllability of Cross structure had been proved and widely accepted, its design and manufacturing technology is pretty mature today, widely used for many machine tools. See figure 1-4 of cross structure XY axes slides.

③ Wire running system

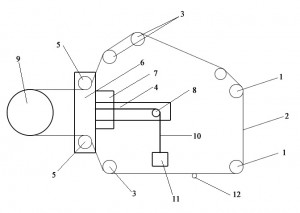

Wire running system controls electrode wire feed at a certain speed and tension, electrode wire feed reciprocally, and coil electrode wire on the wire drum without overlap, figure 1-5 is diagram of wire running system of high speed feed wire cut EDM machine, this system mainly includes guide, wire drum, power contact, tension control units.

1- Main guide; 2-electrode wire; 3- auxiliary guide; 4-linear guide; 5-guides of tightening; 6-slide block; 7- slide of linear guideway; 8-fixed pulley; 9-wire drum; 10-rope; 11-weight drop; 12-electical block(power contact)

While CNC high speed feed wire cut EDM machine is working, guides need to bear fast feeding speed of electrode wire, normally use rolling bearing as guide. There is strict accuracy requirement of “V” groove of guide, the radius of arc at the bottom of groove must be smaller than radius of electrode wire to avoid transverse movement of electrode wire. Basically, reduce the weight of guide at the condition of that guide has met required strength. Beside, the working surface should have enough hardness and low surface roughness.

Wire drum is one of key units to ensure electrode feeding quickly and where to store electrode wire, see figure 1-6. Wire drum does axial moving while turning at high speed, this way, it can coil electrode wire on the wire drum evenly and tidily without overlap, wire drum is able to turn clockwise and counterclockwise to realize wire feed reciprocally. In order to ensure wire drum turn smoothly, inverter was brought into wire cut EDM machine to control the speed of wire drum turning.

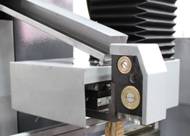

For CNC high speed feed wire cut EDM machine, electrode wire obtain cathode electricity from power feed contact(electrical block), the contact resistance of power feed contact must be very small, otherwise, power feed contact touch the fast feeding for long time, so it must be wear resistant, normally, hard alloy, with good wear resistance and conductivity, is chosen as material of power feed contact.

During process of wire cut EDM machining, electrode is getting loose under impact of direction change, discharging, this situation will affect machining accuracy and surface finish. If there is no tension control unit, it is necessary to tighten electrode manually, when cut large thickness workpeice, cutting quality will getting worse. At present, some high rank CNC high speed feed wire cut EDM machine has weight drop tension control system, it can keep constant tension, save a lot work of operator and increase cutting quality obviously, see figure 1-7 and figure 1-8 wire tension control system of Kingred’s CNC wire cut EDM machine.

④ Taper unit

Taper cutting is realized through taper unit(see figure 1-9).the move axes of taper unit are U and V axes. Usual taper cutting principle is central axis of down guide doesn’t move, fixed, up guide is driven by stepper motor U and V axis and move in four directions. Working table and taper unit are moving simultaneously to realize some angle of electrode.

⑤ Working solution recycle system

Who it works? Pump sucks working solution out of tank, then working solution goes through filter to get rid of unclean stuff; and filtered working solution goes into up pipe and then up and down nozzle separately, then go back to tank through filter net.

It is necessary to change working solution and filter if they affect cutting quality.