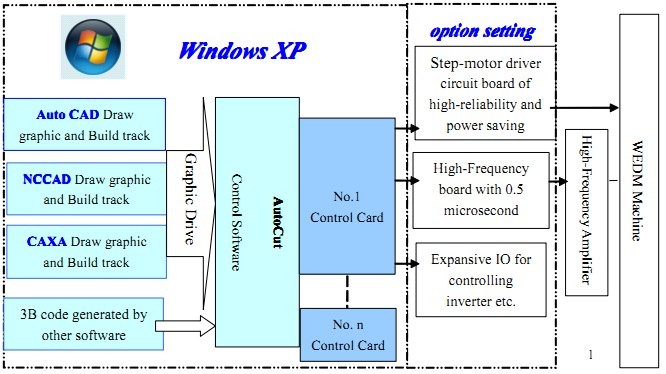

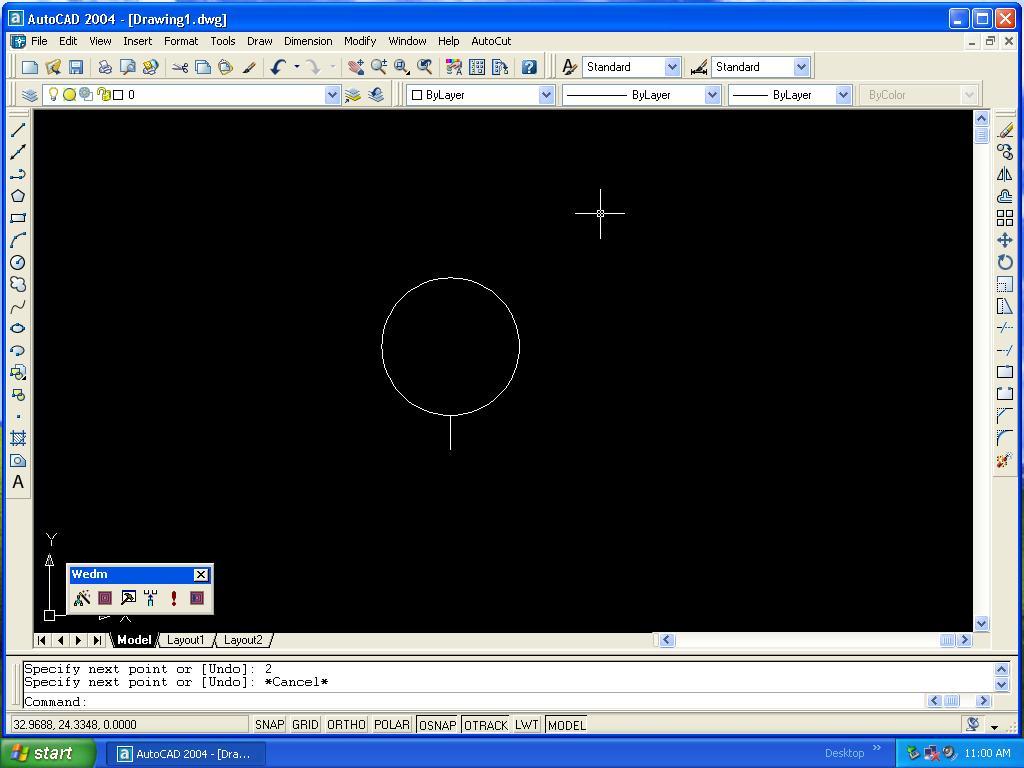

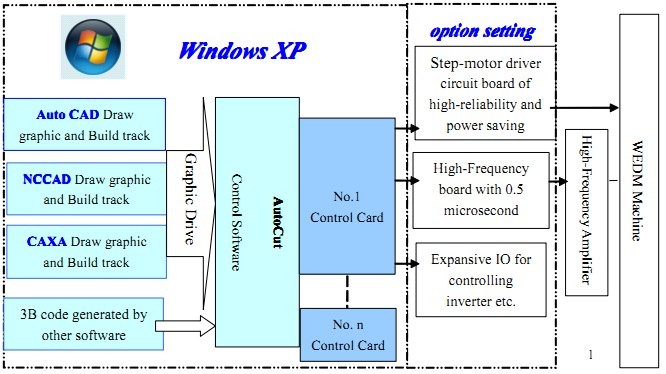

As show in above figure, AutuCUT is a whole integrated solution for wire cut EDM machining. AutoCUT system is consisted by AutoCUT software, PCI based drive card, and high stabile main board of stepper motor drive, and 0.5 microseconds medium speed wire cut EDM high frequency main vibration board. AutoCUT software includes AutoCAD embedded module and cutting control software.

Main function of AutoCUT:

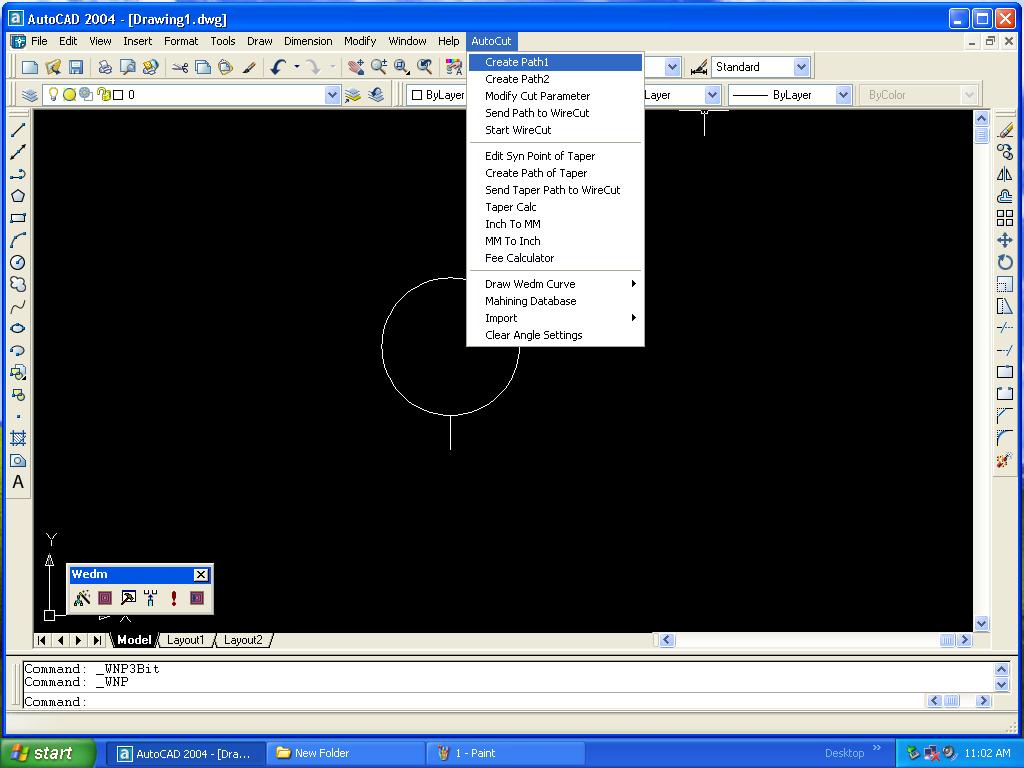

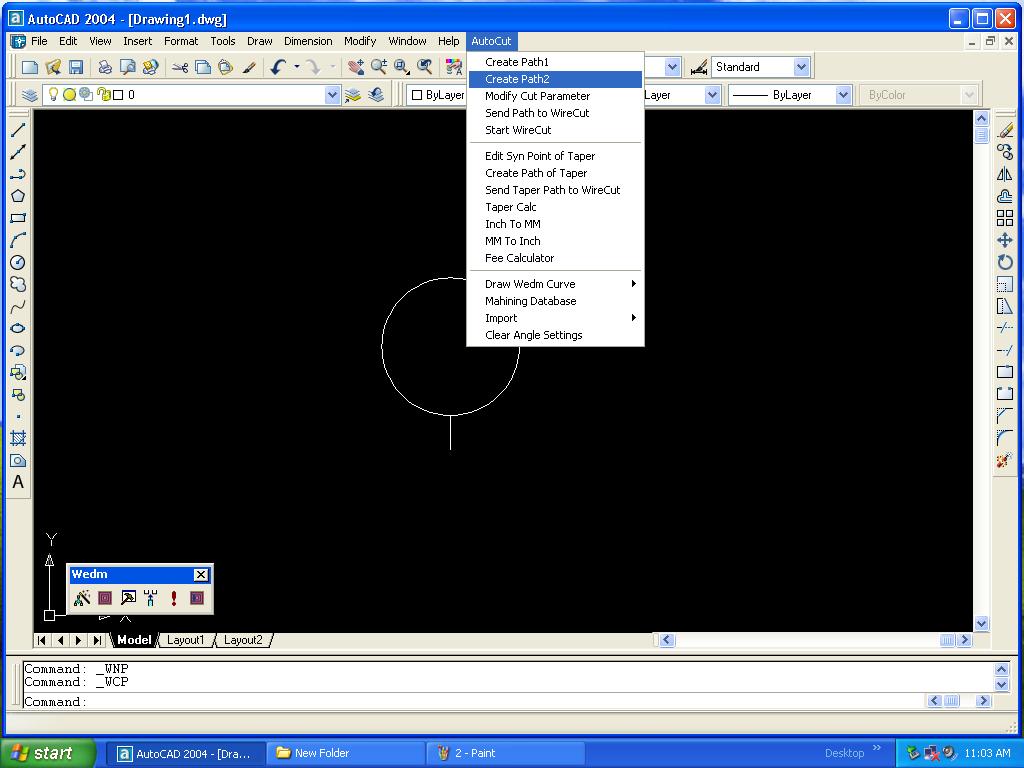

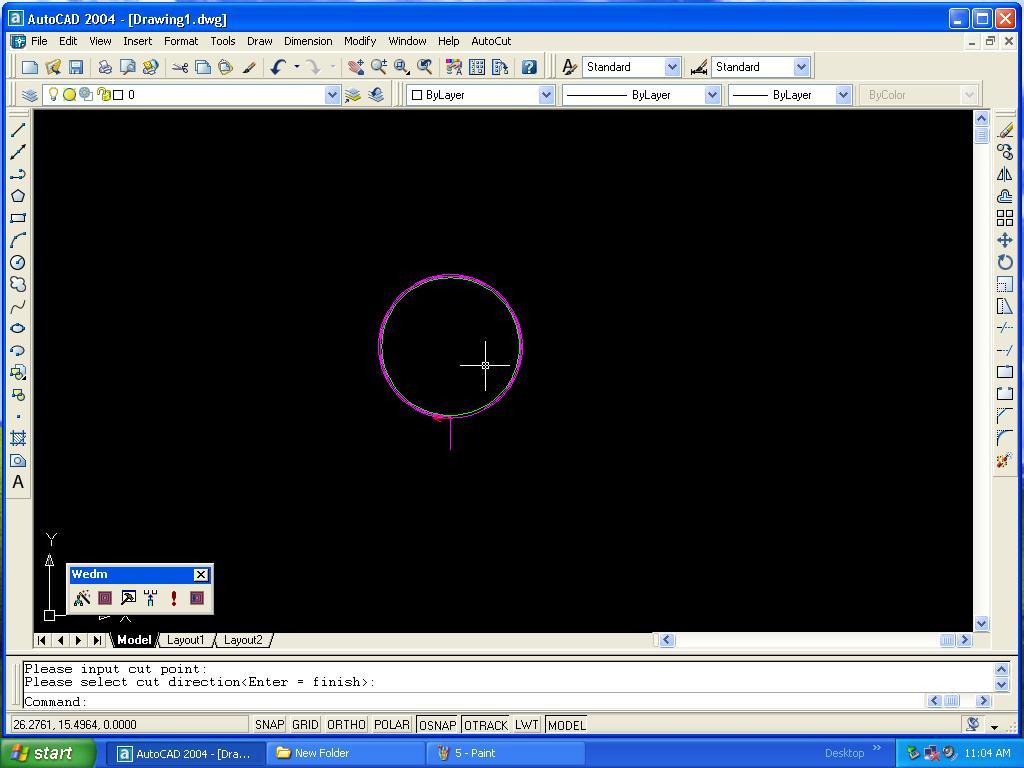

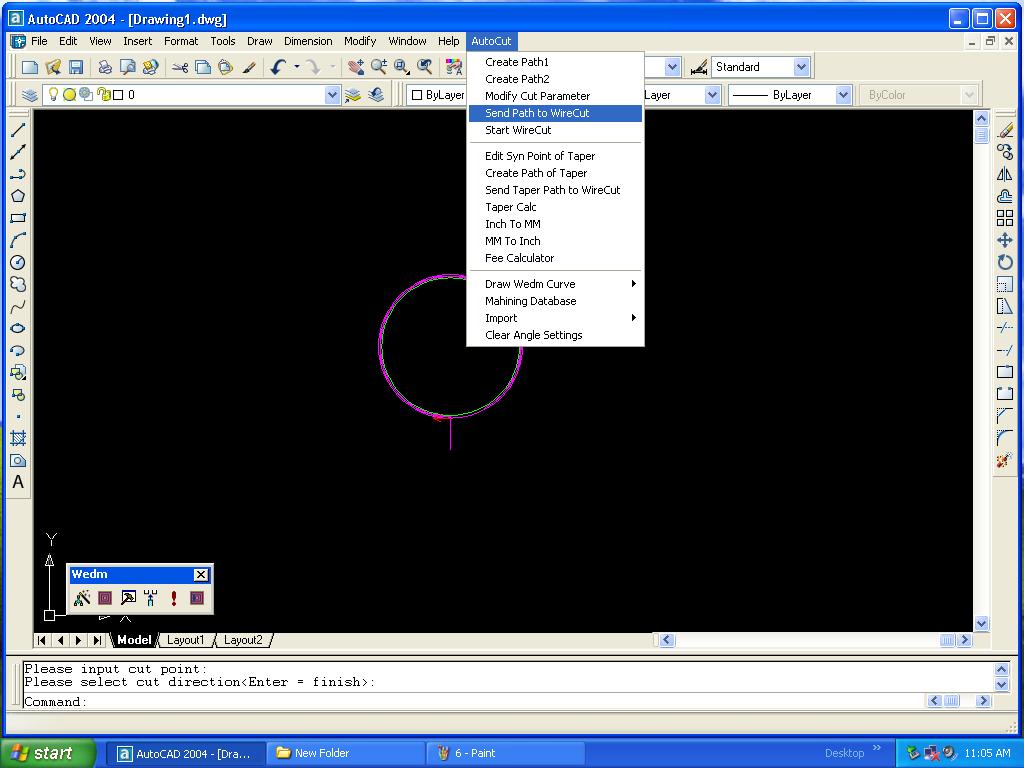

1. Support graph drive automatic programming, there is no need for customers to touch codes, only need to set cutting technology to the graph for cutting; at the same time, it support 3B or G code list created by other wire cut EDM software, and simply read and process to do cutting.

2. Software is embedded in AutoCAD, CAXA and some other software, customers just need to know AutoCAD or other design software, easy to use and no need for special training of drawing.

3. Several machining pattern combined together in cutting(continuous, single segment, forward, backward, trace back and so on.).

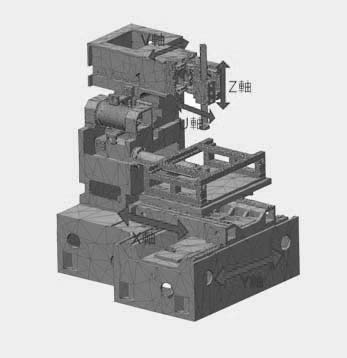

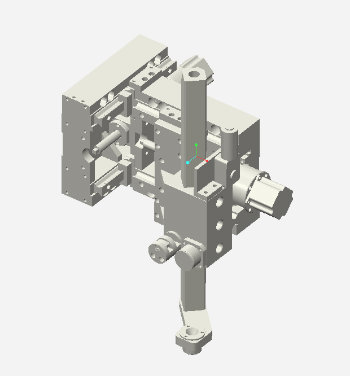

4. XYUV four axes direction change is adjustable, drive motor could be set as 5 phase 10 beats or 3 phase 5 beats and so on.

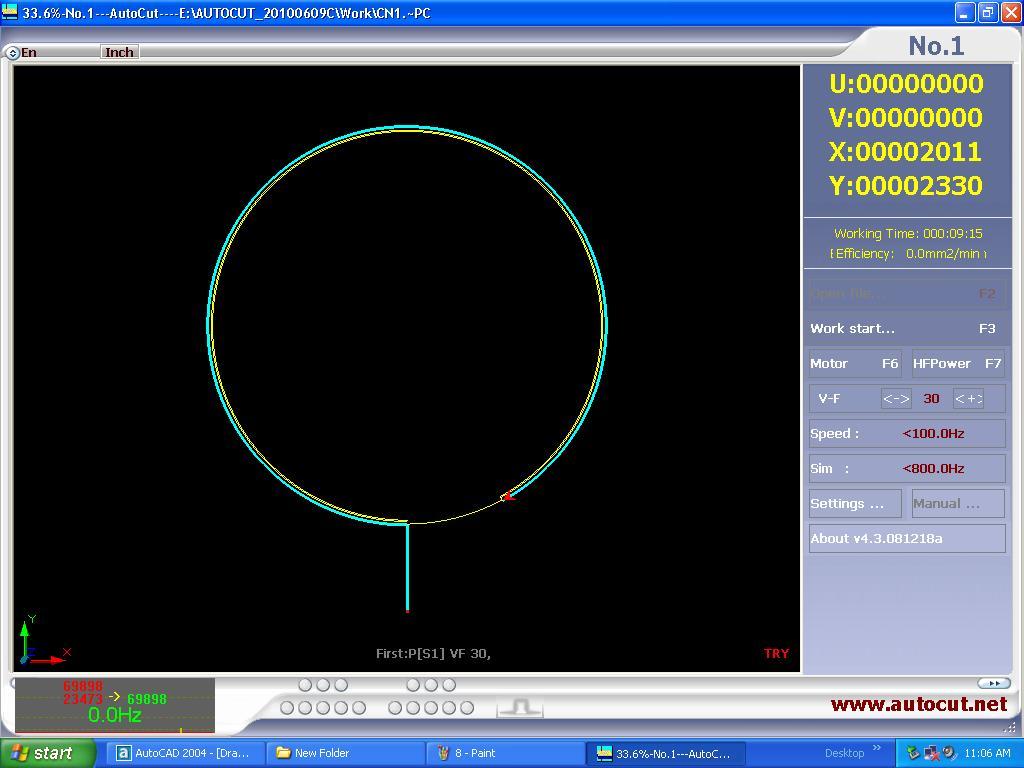

5. Real time monitoring upon X, Y, U.V and cutting situation.

6. Machining preview, real time display of cutting process; 3D display and tracking of taper machining, zoom in and zoom out to view graph, front view, right view, top view and etc..

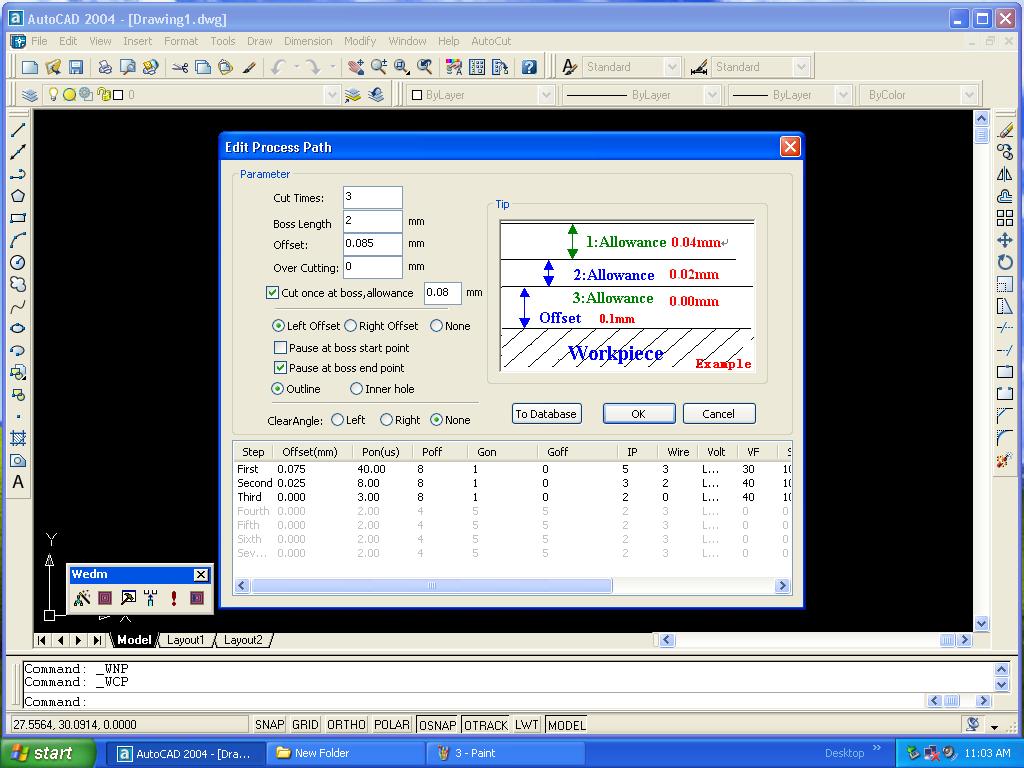

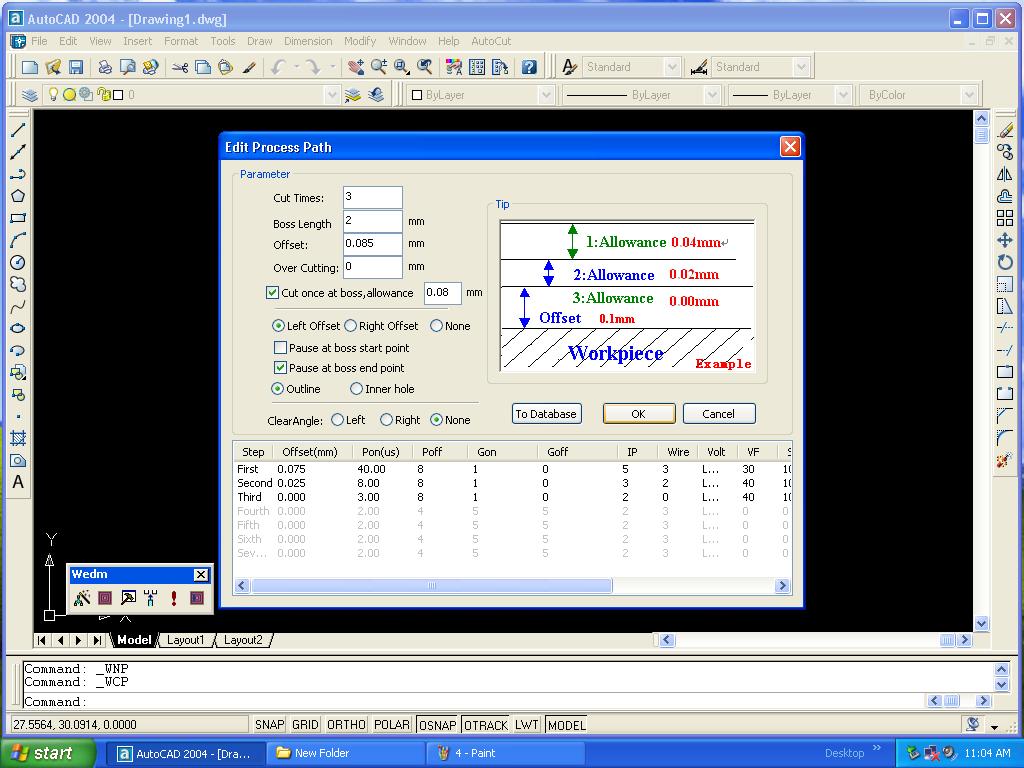

7. Capability of multi-time cutting with customer maintained data base of cutting parameters, make multi-time cutting much more easy and reliable.

8. Taping cutting adopts 4 axes simultaneous technology, can process up and down different shape cutting convenient.

9. Control board to drive 4 axes movement, work stably and reliably.

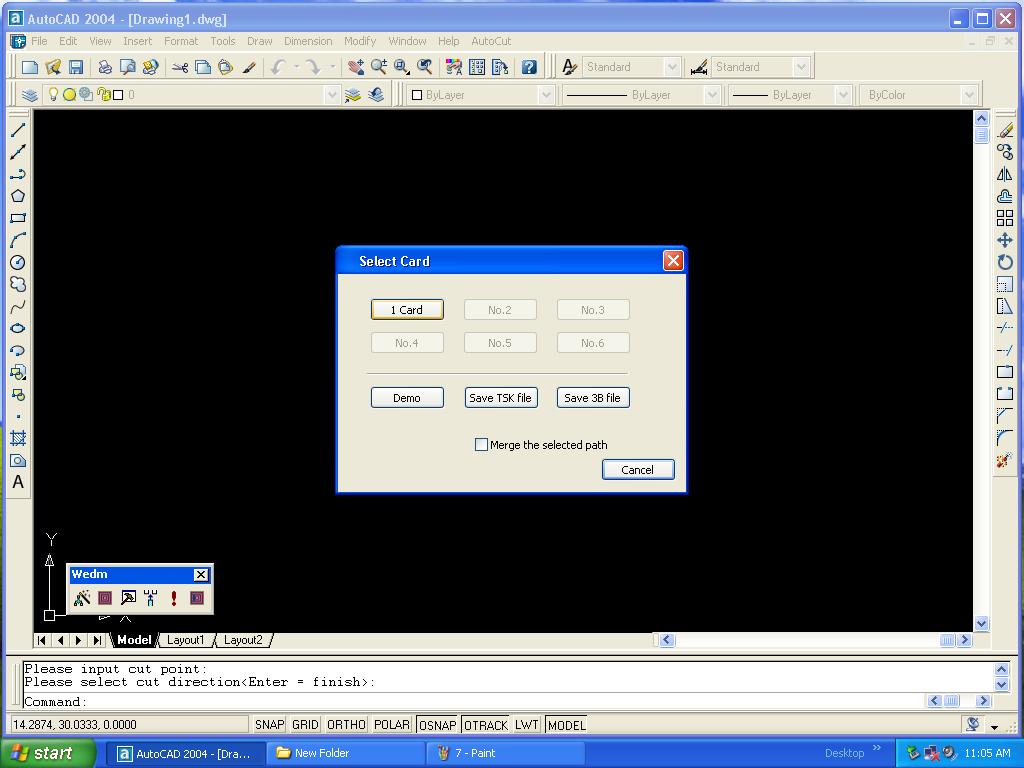

10. Support several cards work together in parallel , several wire cut EDM machine could be controlled by only one computer and do cutting at the same time.

11. With automatic alarm function, it will alarm when cutting is done or malfunction happens, time of alarming is settable.

12. Support angle clear time-delay, time delay when cutting angle of track, to make avoid impact of deviation caused by molybdenum wire.

13. Support compensation of teeth gap of screw to increase mechanical accuracy.

14. Support linear scale and closed- type with servo motors to increasing positioning accuracy of machine.

15. Support three different cutting pattern: normal high speed wire cut EDM machining, medium speed wire cut EDM coding output pattern and output pattern.

16. Power off memory function, cutting data backup after recover of power supply, re-track when short circuit happens and malfunction handling.

17. Automatic power off after machining is done.

Main features of AutoCUT system

1. It adopts graph drive technology, reduce work of man and increase working efficiency, and minimize error caused by workers.

2. Open to various version of WindowsXP, software is easy to learn and use.

3. Directly embedded in AutoCAD, CAXA and may other CAD software, to realize CAC/CAM combined smoothly to prolong cutting range.

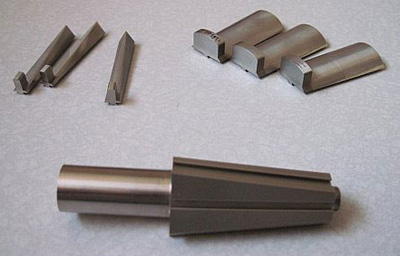

4. Taper cutting; 4 axes simultaneous technology; 3D design and cutting track; compensation to diameter of guide, diameter of electrode wire, and big tap cutting.

5. Multi-cards work simultaneously is supported. It is possible to control many wire cut EDM machines with only one set computer, which has many pieces AutoCUt PCI card.

6. It has data base of cutting parameters which is editable by operators, who can save, edit and read cutting parameters according to different material, different thickness and different needed cutting performance.

7. AutoCUT can optimize processing of super thick workpiece(up to 1000mm) cutting, to make track stable and reliable.